R&R (Remove and Replace) is a key strategy for automotive repair services to manage parts availability. It streamlines work, reduces vehicle downtime, minimizes costs, and ensures top-tier finishes in specialized tasks like paint repair. By conducting inventory audits, replacing obsolete parts with updated alternatives from reliable suppliers, and adopting digital management systems, car repair shops can enhance operational efficiency and customer satisfaction.

In the dynamic landscape of maintenance and repair, effective parts management is key. This article delves into the power of R&R (Remove and Replace) strategies and their pivotal role in Parts Availability Management. We explore the fundamentals of R&R, unraveling its process and benefits. Furthermore, we dissect common challenges in parts procurement and offer robust solutions for successful R&R implementation, ensuring sustainability and operational efficiency. By embracing these strategies, organizations can revolutionize their maintenance practices.

- Understanding R&R: The Basics of Remove and Replace

- Challenges in Parts Availability Management

- Strategies for Effective R&R Implementation and Sustainability

Understanding R&R: The Basics of Remove and Replace

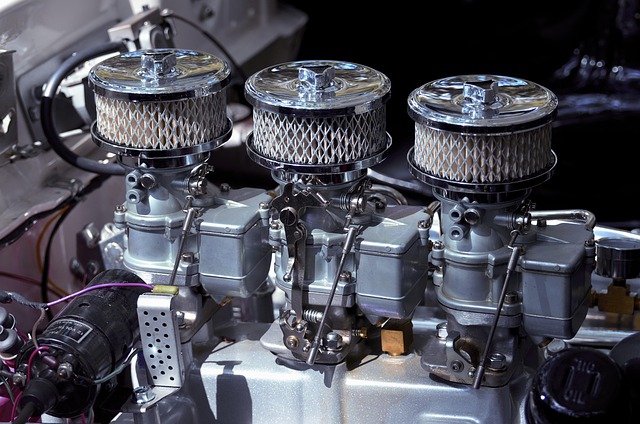

R&R, or Remove and Replace, is a fundamental strategy in parts availability management, particularly within the realm of automotive repair services. It involves a straightforward process: identifying faulty or worn-out components in a vehicle and removing them before replacing them with new ones. This method ensures that only genuine, high-quality parts are used, maintaining the integrity and performance of the vehicle.

In fleet repair services, where efficiency and cost-effectiveness are paramount, understanding R&R is crucial. By implementing this strategy, mechanics can streamline their work, minimize downtime for vehicles, and reduce overall maintenance costs. Moreover, when it comes to specialized tasks like vehicle paint repair, a structured R&R approach guarantees the application of the finest replacement paints, ensuring an impeccable finish that matches the original specifications.

Challenges in Parts Availability Management

Managing parts availability is a complex task for any car repair shop, especially when dealing with older vehicle models or rare components. One of the significant challenges in this process is keeping up with demand and ensuring that essential parts are readily available when customers require them. In the case of collision repair or car dent repair, having the right replacement parts on hand can significantly speed up the service process, enhancing customer satisfaction.

The introduction of R&R (Remove and Replace) strategies offers a solution to these challenges. By implementing efficient inventory management systems, car repair shops can streamline their parts procurement process. This involves regularly reviewing and updating records, establishing robust relationships with reliable suppliers, and adopting digital tools for better tracking. Such measures ensure that when a customer brings in their vehicle for repairs, whether it’s a collision repair or car dent repair, the necessary parts are readily accessible, minimizing delays and providing a seamless experience.

Strategies for Effective R&R Implementation and Sustainability

Implementing an effective R&R (remove and replace) strategy for parts availability management requires a systematic approach. Firstly, conduct a thorough audit of existing inventory to identify obsolete or low-demand components. This process involves analyzing sales data, part usage patterns, and manufacturer recommendations to pinpoint items that can be safely removed from the stock list. Once identified, these parts should be replaced with updated, high-quality alternatives that cater to current market demands and customer needs.

Sustainability in R&R practices is achieved by fostering strong relationships with reliable suppliers. Vehicle repair services and auto glass repair businesses, for instance, should collaborate closely with vendors specializing in vehicle bodywork replacement parts. Regular communication ensures that the latest products and technologies are sourced, enabling these establishments to stay ahead of industry trends. Additionally, implementing digital systems for inventory management allows real-time tracking of part availability, minimizing downtime during repairs and enhancing overall operational efficiency.

R&R (remove and replace) strategies are essential for maintaining efficient operations, especially in industries relying on complex parts networks. By understanding the basics of R&R and implementing effective management practices, organizations can overcome challenges related to parts availability. Through strategic planning, proactive sourcing, and a focus on sustainability, businesses can ensure a reliable supply of replacement parts, minimize downtime, and optimize their overall maintenance processes. This approach is vital for staying competitive in today’s fast-paced market.